ELECTROPNEUMATICS AND HYDRAULICS (I) P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELECTROPNEUMATICS AND HYDRAULICS (I) P.LTD.

Servo Mechanical Presses

Electropneumatics’ Servo Mechanical Presses combine the speed and reliability of the eccentric drive mechanical presses and the flexibility of hydraulic presses with innovative electric servo technology to open up new opportunities for automotive, auto component, appliance and general engineering applications. Independent programmability of slide and cushion speeds and motion sequences make blanking, shallow drawing, trimming, coining, too tryout, transfer/progressive die operations, etc. possible on the same press.

The large, high-performance AC torque motors drive the eccentric gear arrangement replacing the flywheel, clutch and brake and offering dynamic control over forming operations and energy savings.

- Energy consumption less than conventional presses

(even up to 40%). - Flexibility to perform different forming processes through

slide and cushion speed, stroke and motion sequence

programming- blanking, drawing, forming, progressive

die operations, tool tryout, etc. - Higher productivity than conventional presses

(sometimes up to 60%) since motion sequences can be

optimally tuned and synchronised with automation devices. - Reduced vibration, impact and noise levels leading to

superior part quality. - Improved die and press life.

- Smaller footprint, especially for large bed presses.

- Suitable for all materials, especially high strength steels.

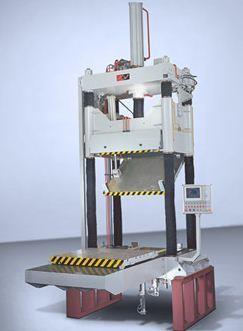

Hydraulic Moulding Presses

Composite materials are substituting steel and aluminium for manufacturing automotive structural parts and skin panels with first-class surface quality because they are light-weight and yet structurally strong. Electropneumatics presses for forming and moulding of engineering plastics/composites (such as SMC, DMC, FRP, epoxy, etc.) and also automotive interior fabrics and friction material for brake and clutch facings meets this demand. These machines have features specially designed to control the forming, heating and cooling cycles and accurately level, form and eject parts to achieve Grade I component surfaces.

Hydraulic Die Spotting Tryout Presses

The need for quick and reliable die/mould tryout is constantly increasing because of the increasing number of new models and smaller batch quantities that are being produced in the automotive industry. In addition, forming processes have become complex, especially with the newer difficult materials. Therefore, it has become necessary to break-in and prove dies (new and reconditioned) well in advance of production start to save expensive production time. Electropneumatics’ Die Spotting and Tryout Presses have all the features needed to accurately simulate the actual manufacturing process for die prove-out. These presses can be used for die inspection, mould finishing and limited batch/prototype production.

Hydraulic Powder Compacting Presses

Electropneumatics designs and builds tailor-made powder compacting and sintering presses for near-net shape forming of parts. Powders of iron, steel, high speed steel, carbides, ceramics, friction material, bronze, copper and their alloys can be formed into complex parts of high strength. Our presses can be used for dry and wet compacting and come with a wide variety of options, sophistication and automation for large volume, continuous production. These are hydraulic high-efficiency automatic presses that can be supplied with sophisticated precise tools and tool adaptors to ensure production of complex parts to high quality levels. Sintering and sizing presses are also available.

Multi Station Transfer Presses

Electropneumatics builds high performance multi-station presses for volume production of formed sheet or solid parts. These highly productive machines are characterised by their flexibility and repeatability. The operations can be performed by a single ram or with multiple rams having independent controls of speed, force and position. These multi-station presses can be equipped with automatic electric AC servo transfer systems for feeding of blank/part from start to end. Transfer presses are completely automated to perform all tasks from blank/coil to finished product, without human intervention. Several optional automation solutions are available as per application and requirement.

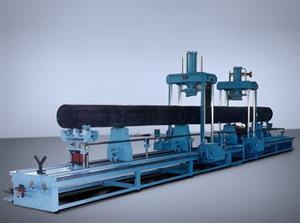

Hydraulic Honing Machines

- Light duty - for small parts such as two-wheeler engine master and brake cylinders, connecting rods, rocker arms and gears, valve and pump bodies

- Medium duty - for compressor blocks, multi-cylinder engine blocks and liners, extruder barrels, hydraulic and pneumatic cylinder barrels

- Heavy duty - for large, long parts such as heavy vehicle engine blocks, process industry tubes and liners, big hydraulic and pneumatic cylinder barrels

- Special - with multi-spindles and automation for high volume production

Tube Processing Machines

The end forming machines are meticulously designed, proven and reliable. The end formed parts produced by this chipless process have increased strength, good surface finish and tight tolerances. Special multi-section punching machines for programmable punching of holes in round, square, rectangular, oval and other sections are also available.

End Forming Machines

- Cold forming of intricate shapes and profiles- heading, flaring, swaging (expanding/reducing), beading and others are possible

- Available in one, two or multiple stages with linear or rotary indexing facility

- Can form one or both ends of the tube simultaneously

End Cutting Machines

- Square end trim cuts, angle, radius and scallop cuts

- Incorporates dual blade shear and supported shear technologies

- End cutting systems can be incorporated on tube benders

Punching Machines

- Hole punching in tubular (round, square, rectangular, oval) and other sections

- CNC programmable hole pattern

Multi-Station Tube Processing Machines

- Suitable for performing a combination of end forming, cutting, punching, bending, etc. on one machine

Power Transmission Line Equipment

Description / Specification of Power Transmission Line Equipment

We are involved in offering a wide range of Power Transmission Line Equipment to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Power Transmission Line Equipment. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

Ac Servo Drives And Systems

Electropneumatics has its own indigenously developed range of AC servo drives and a family of brushless servo motors for a variety of applications. Designed with the latest DSP and IGBT technologies, these state-of-the-art drives provide exceptional system performance at an unmatched price. They are precision manufactured and 100% tested under load. Besides use in our own machines, they can be used in any application requiring accurate control and flexibility of operation. We supply the motors and drives along with the mechanical system as a total solution.

SERVO DRIVES

SPM-2X Series (up to 10A)

These all digital dual axes servo drives are the lowest cost per axes drives available. This compact drive module can control two motors simultaneously as independent axes with numerous control options. Apart from direct cost savings, this highly integrated module indirectly saves user cost due to reduced wiring, reduced control panel space and reduction is power due to common power utilization regeneration. Ideal for CNC XY tables, routers, automation systems, etc.

EPSD Series (up to 35A)

The EPSD series consist of higher power drives for larger motors (above 10 Nm). These rugged drives are available in 220V as well as 415V options, thus enabling the use of a very wide range of motors. Different control options are possible. They in application in CNC machines, robotics, automation, packaging machines etc.

1DSC Custom Series

In addition to standard drives, Electropneumatics offers custom solutions for specific and demanding applications. These custom solutions are provided as per the customers requirements and includes special purpose drives for low voltage battery operation, direct drive torque motors, linear motors, etc. They are used in harsh environments and user-specific stringent requirements’

BRUSHLESS SERVO MOTORS

Our AC servo systems are fitted with brushless servo motors of international repute. They seamlessly integrate with our drive systems to guarantee high performance in terms of reliability, efficiency, long life of motor and electromagnetic immunity. Available from 8.5 Nm up to 60 Nm in compact dimensions, they are ideal for applications such as automatic machines for forming of metal, wood, plastic, glass and ceramic as well as for packaging and sorting equipment. They also find use in robots, handling equipment and pharmaceutical industries.

The series of direct drive torque motors combine high torque rating with significant accelerations and decelerations. Their unique construction, where load is mounted directly on the drive rotor provides advantages such as elimination of traditional kinematics chain, reduced maintenance, shortened mounting time and substantial energy saving. Available in torque ratings from 2 Nm up to 70 Nm.

Servo motors designed and developed to meet user requirements are also available when volumes are substantially high.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.